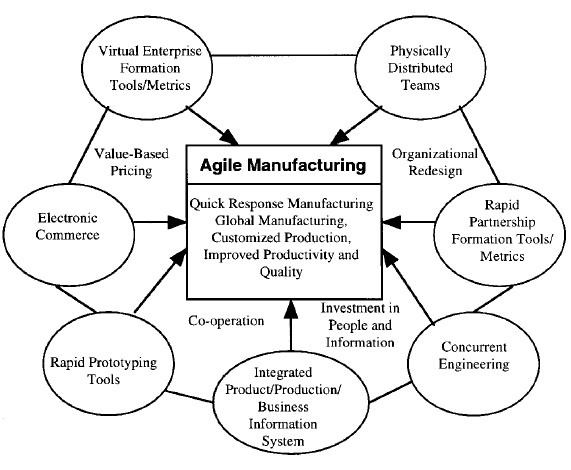

Agile manufacturing is a term applied to an organization that has created the processes, tools, and training to enable it to respond quickly to customer needs and market changes while still controlling costs and quality.

An enabling factor in becoming an agile manufacturer has been the development of manufacturing support technology that allows the marketers, the designers and the production personnel to share a common database of parts and products, to share data on production capacities and problems ¡ª particularly where small initial problems may have larger downstream effects. It is a general proposition of manufacturing that the cost of correcting quality issues increases as the problem moves downstream, so that it is cheaper to correct quality problems at the earliest possible point in the process.

Agile manufacturing is seen as the next step after LEAN in the evolution of production methodology. The key difference between the two is like between a thin and an athletic person, agile being the latter. One can be neither, one or both. In manufacturing theory being both is often referred to as leagile. According to Martin Christopher, when companies have to decide what to be, they have to look at the Customer Order Cycle (the time the customers are willing to wait) and the leadtime for getting supplies. If the supplier has a short lead time, lean production is possible. If the COC is short, agile production is beneficial.

Goldman et al. suggest that Agility has four underlying components:

1.Delivering value to the customer;

2.Being ready for change;

3.Valuing human knowledge and skills;

4.Forming virtual partnerships.

» More Information